Detail

The pump system used permanent magnet motor, compared to induction motor pump system. Thanks to its advantages listed below, which is to be used that have variable water requirements provides up to 35% energy saving and improves the pump’s service life.

Soft Start and Longevity

Excessive current drawn during the star-delta of the electrical motor (starting current) and the mechanic loads are eliminated thanks to the soft start and stop features of this system. As a result, longevity of the motor equipment improves and maintenance costs decrease.

Economical Run and Constant Output Pressure

When the conventional electric motor pump switches on, it keeps working at its constant speed, most of the time, the pump doesn’t need the full load operation, this wastes a lot of power long terms. Pumps with our permanent magnet motor, works at an optimum speed (rpm) to meet the real time water needs and provides great deal of energy savings as well as producing targeted constant output water pressure.

1. Pump used permanent magnet motor systems.

1.1 Purpose: In variable speed pumps, the conventional motor system is Induction Motor+ VFD (Variable Frequency Driver); the permanent magnet motor system has higher efficiency and wider speed range, which can meet the variable speed pumps better. This case is trying to optimize the motor system to develop a higher cost performance variable speed pump system.

1.2: Performance requirements.

1) Power=1600W,5000RPM

2) Diameter of Stator: 110mm( to compatible with current housing)

3) Starting sensor less

4) Sinusoid driven, power factor PF=1, continuous duty

5) Interface customized

6) Vertical Pump system design

2. Permanent magnet motors in water supply, pressurization system

2.1 Purpose: high efficiency water supply, pressurization system, upgrade or replace the current AC VF(variable frequency) system.

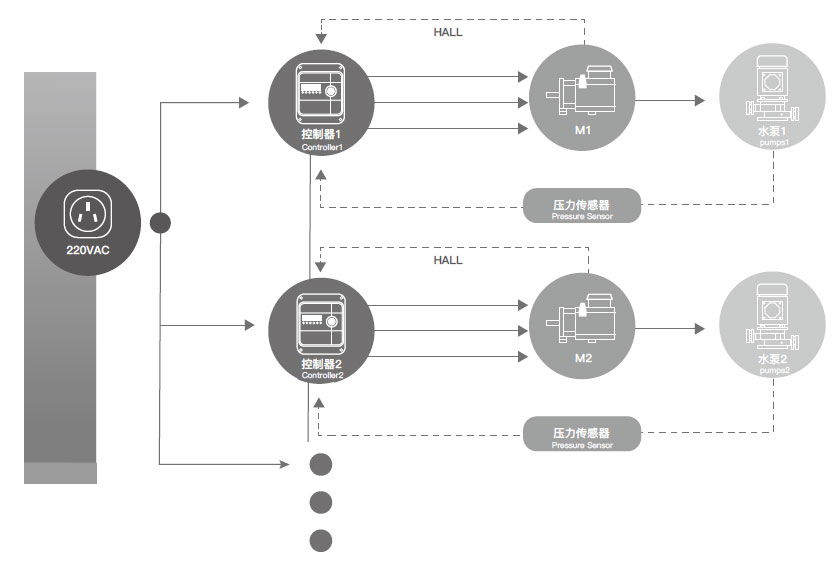

2.2 system description

1)Power:0.75-7.5KW,3600RPM,

Motor 3KW( equal Vertical motor mounting dimensions),3600RPM, 3 sets

2)Voltage: 380VAC����,50/60HZ

3)Vertical motor power and installation dimensions are the same to the IEC, drive and motor integration design and installation

4)Pumps 2-4 sets

5)Set the host and system pressure (automatic switching, timing switch)

6)constant pressure automatic on-line operation (control system and operating frequency of each machine)

7)system of sleep (State of no using water (pressure / power changes) down, start with water

8)dry run protection (a pressure switch or water level detection electrode)

9)working interface, interface, running function customized

10)The corresponding driver suitable for speed control, constant pressure operation

This system is widely used in residential water supply system, campus water supply system or industrial water supply system etc.

For a professional pump case advices, please contact us at info@volcanomotor.com. Our engineers are at our service case by case. You can try tell us your pump application, function requirements, efficiency etc. our permanent magnet motor pumps systems can easily replace the conventional 3 phase asynchronous electric motors with higher efficiency and intelligent.

Keywords: Intelligent pump system, Permanent magnet motor system, high efficiency motor system, Pump used permanent magnet motor, constant pressure water supply pumps, variable speed motors. Energy saving pump system.